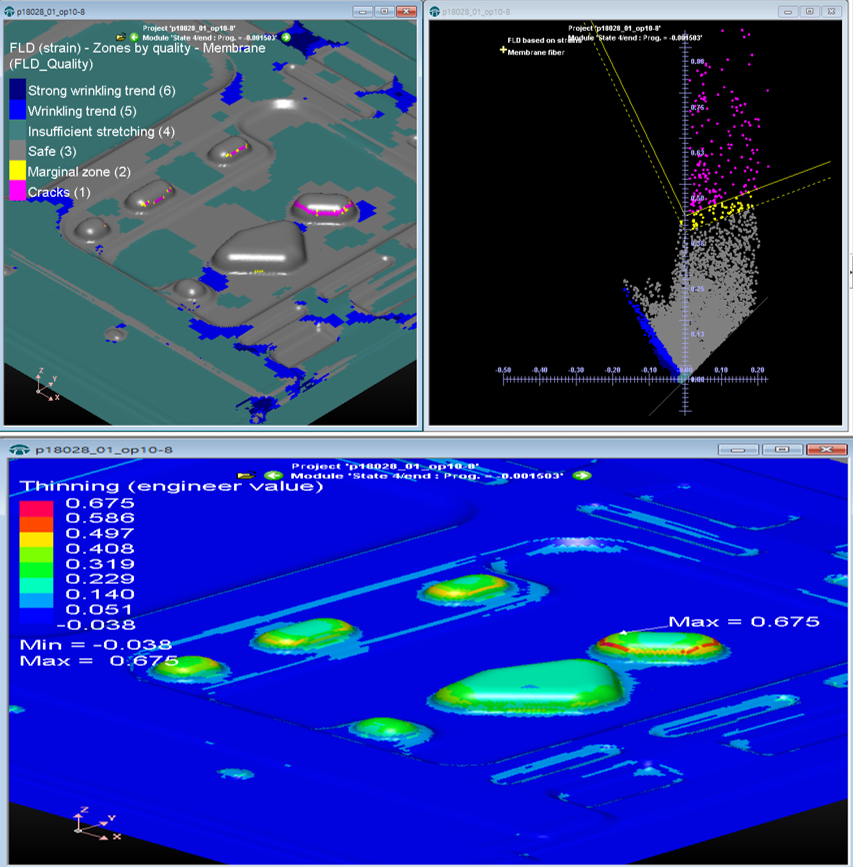

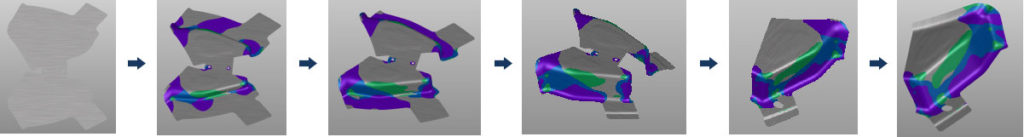

It is important initially to have a basic idea of the forming process, our engineers conduct CAE simulation prior to preliminary tool design, the result of the CAE analysis is then used in tool design.

* We analyze forming process and its logic for each stamping station;

* Complete “ Process review record”

* Complete “ CAE Analysis report”

* Compare forming data of each station against part 2D&3D data.

* Design structure static evaluation and dynamic simulation

* Complete “Structural review record” and “DFMEA”

* Check if travel and forces of motional parts are consistent and matching with simulation